Silver Ball Matrix Sockets

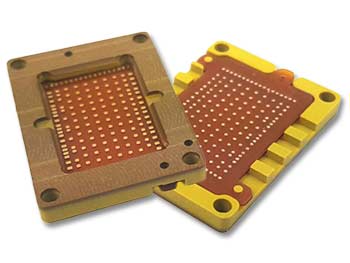

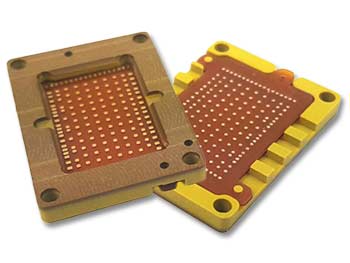

SM Contact is a unique contact that has precise silver balls held together by a proprietary conductive formulation. These conductive columns (diameter optimized for 50 ohm impedance) are suspended in a non-conductive flexible elastomer substrate with a patented solid core for enhanced durability and reliable performance over time, temperature and cycles. This flexible substrate is very compliant and resilient and enables the conductive columns to revert back to original shape when the force is removed. Solutions are available for 0.25mm to 1.27mm LGA, BGA, QFN, CSP, POP, WLP and other packages.

The silver ball matrix contact technology is also available with a protective plunger matrix (a gold plated copper cylinder) that sits on top of the conductive columns. This plunger matrix protects the conductive column from contamination from various solder ball interfaces. A quickly replaceable plunger matrix enables minimal downtime during final production test. The product family code for this line of sockets is SMP.

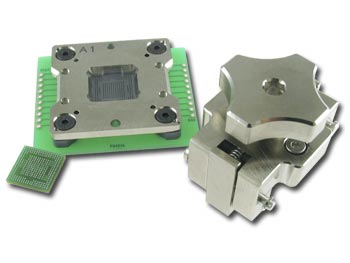

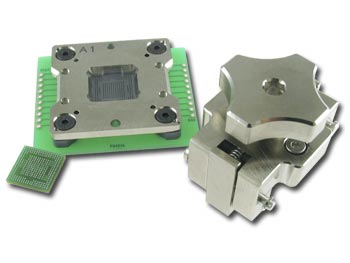

Ironwood Electronics SM sockets are small footprint sockets and compatible with other Ironwood socket line for switching contacts to test different applications. The socket needs about 2.5mm extra space around the chip than the actual chip size utilizing only very small PCB real estate. Various lid options are available such as swivel lid, clamshell lid with a wave spring, double latch lid to provide the compression force. If heat dissipation is of concern, a heat sink can be integrated in the middle of any type of lid to dissipate up to 100 watts.

Typical specifications for the SM/SMP contact technology include:

- Over 40GHz bandwidth @-1dB for edge pins

- Contact resistance under 15mOhms

- Self inductance under 0.21nH

- Capacitance under 0.15pF

- Operating temperature range -55C to +150C

- Insertion/Extraction life over 500, 000 cycles with protective plunger matrix

- Current rating at 14C temperature rise is 4 Amps per pin

There are three options available to mount these sockets. The socket can be mounted using hardware and needs holes for screws and can be positioned on the target board. If the holes cannot be drilled on the target board, epoxy mount sockets are the other option. Epoxy mount sockets use epoxy and special mechanism to mount the socket on the target board. The third option is using SMT emulator base. The SMT emulator base has balls on the bottom side that precisely matches the device array and has hardware for socket mounting.