Water-cooled solutions refer to the use of water as a cooling medium to dissipate heat generated by various devices or systems. This technology is commonly used in high-performance computing, industrial machinery, electronics, and even some high-end gaming PCs. Water has a higher heat capacity and thermal conductivity compared to air, making it more efficient for transferring heat away from heat-generating components. When testing semiconductor devices in a socket, heat is generated based on the device functionality and its specification. This heat needs to be removed for proper functioning of devices while testing is in process. Otherwise, accurate device characterization or validation cannot be achieved.

There are a few different types of water-cooled solutions. Closed-loop all in one coolers is the better choice since they are pre-assembled and sealed units that include a pump, water block, radiator, and fans. These coolers are easier to install and require less maintenance compared to open-loop systems. Water-cooled systems are often quieter than air-cooled systems, as water transfers heat more efficiently, requiring fans to run at lower speeds to achieve the same cooling. There is a risk of leaks that could potentially damage components if not properly maintained or if a component fails. Water-cooled solutions can provide significant benefits in terms of cooling performance and aesthetics, but they require careful consideration, planning, and maintenance to ensure successful implementation. Below are some example designs delivered to our customers and field implemented successfully.

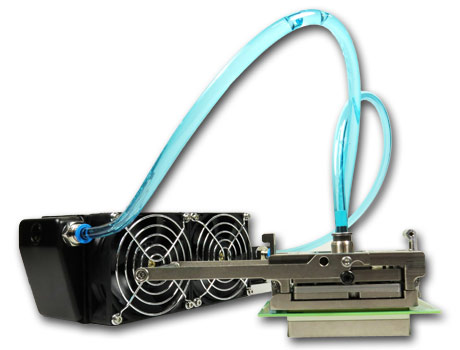

400 Watt Integrated Radiators

It is important for applications exceeding 300W to not only be able to dissipate the heat from the device but also rapidly remove it. Fluid based solutions are a method to accomplish both while being able to be adapted to almost any existing socket or adapter solution. Ironwood is familiar with a wide variety of radiator and pump solutions on the market and can pair the correct solution to any given application. Figure 1 shows one such solution for a 52 x 42mm device, 0.9mm pitch, 300W, and a 80mm x 160mm radiator.

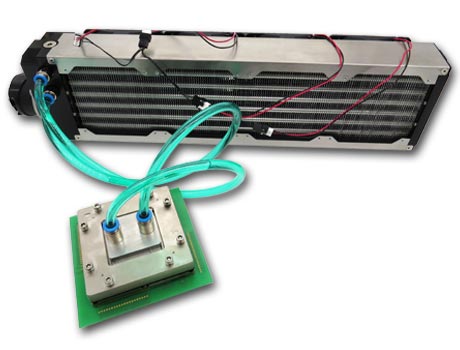

1200 Watt Integrated Radiators

Figure 2 shows a test socket for BGA6500 device which typically generates power of 1000 watts. Socket is designed with a water block assembly which has top component that has interfaces for water inlet and outlet. The bottom component has channels for water to flow through all surfaces for heat dissipation. Bottom component is made of copper and sealed with top component which can be aluminum for closed loop system. Inlet and outlet tubes are connected from pump to the top side of water block assembly. Pump pushes hot water into radiator where the heat is condensed thereby circulates cold water back to water block which in turn pulls more heat away from device that is in contact with the water block bottom component. The cycle continues as long as the test is in process and device temperature is maintained below 125C.

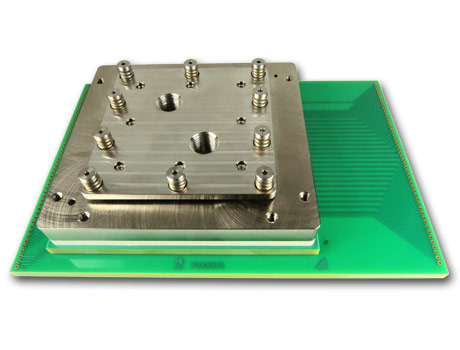

1500+ Watt Water Block for Chillers

Many test labs already have cold water or chillers available. For these applications custom water blocks are designed to mate up with the existing system. These independent units can be used inside the socket or sometimes interfaced with TEC (Thermo Electric Cooler) for improving cooling efficiency. Figure 3 shows a solution for a 90mm x 80mm device on a 0.9mm pitch, with an independent force controlled water block. The water block is rated for 1500W, thermal resistance of 0.03 C/W, and a 1.2 psi pressure drop.

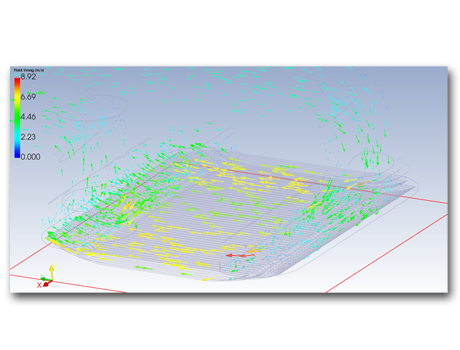

CFD Simulation Capabilities

Ironwood has decades of experience integrating thermal requirements into both socket and adapter designs. Any new thermal design goes through extensive simulations utilizing the requirements of the application.

Thermal simulation capabilities:

- Natural convection heatsinks

- Forced convection heatsink + fans

- Heat pipes

- Cold plates

- Water blocks for radiators

- Water blocks for chillers

- TEC based systems

Custom designs are our specialty. We have found that it is most effective for us to ask customers for information about the specific application and then provide a quote. You can fill the form with required information or call us at 1-800-404-0204.