Ironwood has created thousands of custom solutions for customers worldwide. A few recent ones are illustrated.

Ironwood Electronics has the largest, most experienced engineering staff in our industry. Quick turn custom solutions are our specialty, with some custom solutions available as fast as 1 week. Our engineers utilize advanced tools to design precision and quality into each product. We are dedicated to providing high quality services that meet or exceed customer requirements.

Many of our innovative designs incorporate technologies such as:

- Controlled Impedance

- 0.8mm pin grid arrays

- Blind/Buried Vias

- 3 mil Line & Space

- Embedded Resistors

- Laser Micro Vias

- Shaped Solder

- Flexible PCBs

- Spring Pin Socket

- Elastomer Socket

- S-Parameter Simulation

- Thermal Simulation

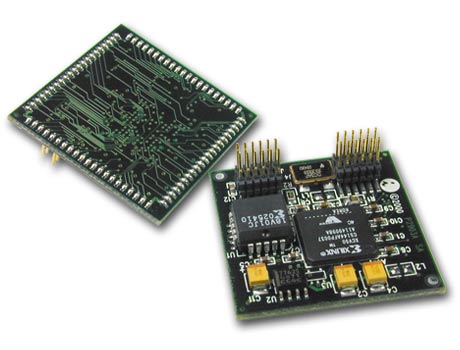

Custom adapter upgrades PLCC footprint to BGA device:

Upgrade your old PLCC device with custom adapter that has Xilinx FPGA, PROM, Oscillator, voltage convertor, etc. Custom adapter utilizes Ironwood’s solder column technology that can be placed in a target board which has only SMT pads using standard reflow method. These custom parts are made out of FR4 with eutectic solder.

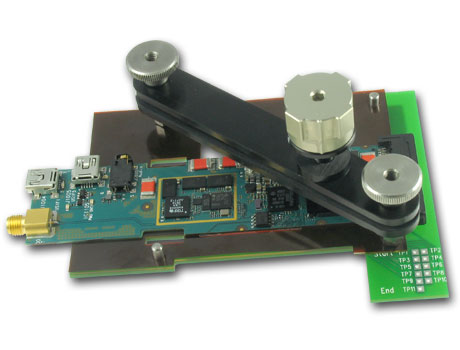

Board-to-board interconnection module using high performance connector:

Connect a custom module to target PCB using Ironwood’s high performance board-to-board connector. This custom interconnect module Involves custom mechanical design, finite element analysis for proper stress and deflection, tolerance stack up analysis for proper compression and reliable connection throughout the product life.

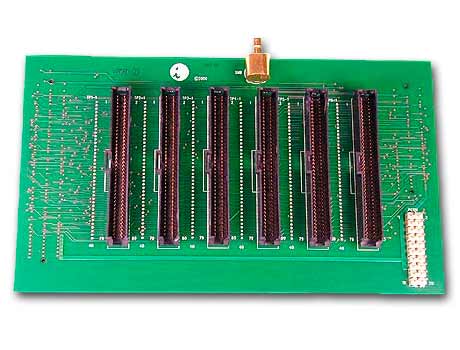

Custom connector adapter simplifies interface to other modules:

Target board has 200 and 120 position SAMTEC connectors. The daughter card module has 80 Position, 0.050″x0.100″, SAMTEC connector. Ironwood custom adapter made out of FR4 and connector receptacles transfers signals from daughter card to mother board without performance loss.

Right angle DIP socket receptacle:

Because of space constraints a DIP device cannot be placed on the target PCB. A right angle socket adapter plugs or solders into the target PCB and the DIP device is plugged vertically away from space constraint.

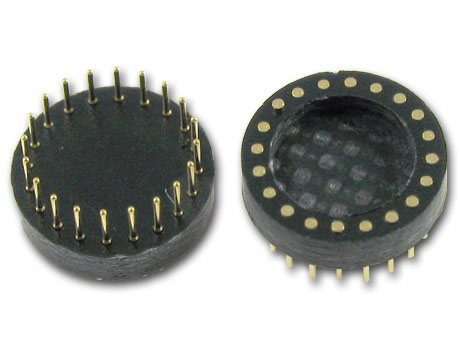

Custom connector converts SMT device to thru hole device:

Using this custom convertor a SMT device can be placed in a target board which has only plated thru holes for soldering pins. This custom part is made out of FR4 and gold plated machined pins.

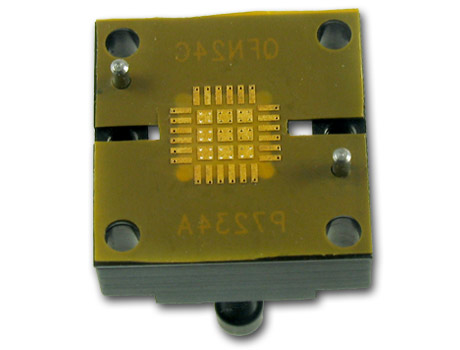

Custom socket allows impedance tuning:

Inductors, capacitors, resistors need to be placed very close to specific signal pin for tuning impedance to 50 Ohms. Custom cutout in the socket shown allows passive components to be very close to active signal pins.

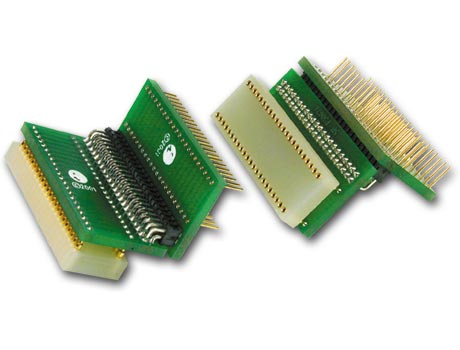

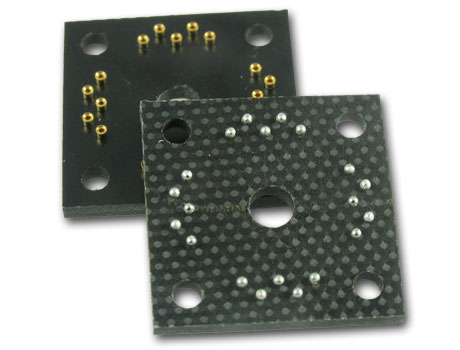

Custom connector converts thru hole device to SMT device:

Using this custom convertor a thru hole device can be placed in a target board which has only SMT pads. These custom parts are made out of FR4, gold plated receptacles and solder balls.

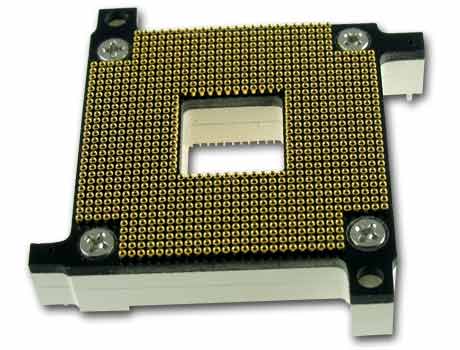

Custom connector converts thru hole device to solder less mounting:

Using this custom convertor a thru hole device can be placed without soldering in a target board which has only SMT pads. This custom part has spring probes on the bottom side and gold plated receptacles on the top side to receive Pin Grid Array device.

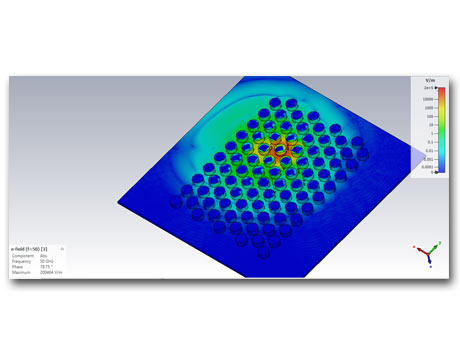

S-parameter Simulation Capability

Microwave/RF system complexity has been increasing and thus the challenges in design, test and implementation are greater than ever. Ironwood Electronics offers S-parameter simulation results for socket contactors to design engineers in a very cost-effective and timely manner. Using S-parameter results, design engineers can select appropriate socket contactors for their high frequency test applications. Ironwood Electronics uses CST MWS® simulation tool.

Please contact Ironwood Electronics for further detail.

Ordering Custom Solutions

We are pleased to quote custom solutions based on your requirements. To speed quoting, please provide the following:

- Quantity needed

- Delivery requirements

- Description of application