Stamped Spring Pin Sockets

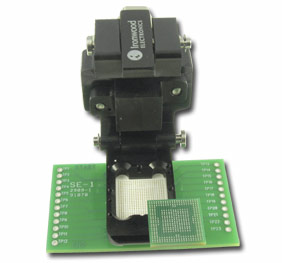

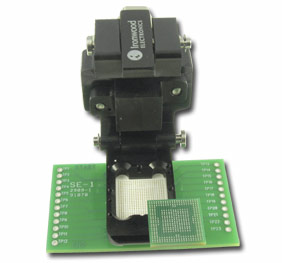

Ironwood Electronics SBT sockets are small footprint sockets that are compatible with other product lines such as GHz elastomer sockets, Giga-Spring sockets, etc. The socket needs about 2.5mm extra space around the chip than the actual chip size utilizing only very small PCB real estate. A heat sink screw on the top provides the compression force as well as thermal relief and can be customized to dissipate more power. SBT socket uses SBT contact technology for high endurance and wide temperature applications. SBT Contact is a stamped contact with outside spring as well as inside leaf spring that provides a robust solution for Burn-in & Test applications. Solutions are available for 0.3mm to 1.27mm LGA, BGA, QFN, QFP, SOIC and other packages. Contact technology has 3 part system which includes top plunger, bottom plunger and a spring. The Beryllium Copper plungers are stamped and assembled to a stainless steel spring in an automated system to enable fast turnaround time, low cost and zero defects.

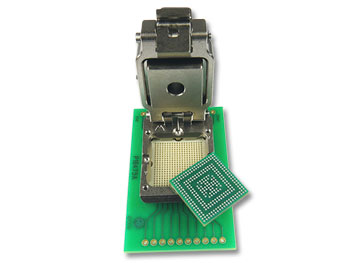

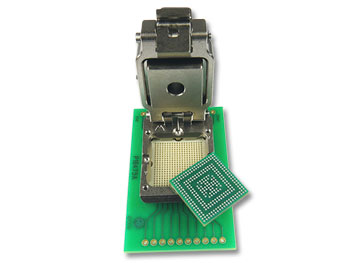

To use, drop the IC into the socket, place the floating compression plate over the IC, add the swivel lid (with key-hole slots), and apply a normal force to the IC using the compression screw. Alternately, these sockets come with easy open/close clamshell lids for quick chip replacement. SBT sockets can be used for hand test or quick turn custom burn-in applications with the most stringent requirements

Typical specifications for the SBT contact technology include:

- 4GHz – 31.7GHz bandwidth @-1dB

- Contact resistance under 15mOhm

- Self inductance 0.88 – 0.95nH

- Capacitance under 0.3pF

- Operating temperature range -55C to +180C

- Insertion/Extraction life over 500,000 cycles

- Current rating at 80C temperature rise is 4A – 8A per pin

* Detailed specifications for specific pitch are shown above in the Technical Documents table in a separate report.

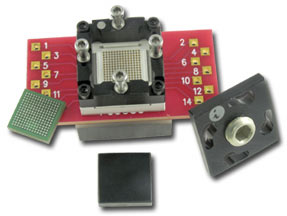

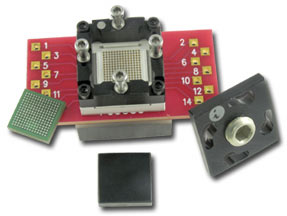

There are three options available to mount these sockets. The socket can be mounted using hardware and needs holes for screws and can be positioned on the target board. If the holes cannot be drilled on the target board, epoxy mount sockets are the other option. Epoxy mount sockets use epoxy and special mechanism to mount the socket on the target board. The third option is using SMT emulator base. The SMT emulator base has balls on the bottom side that precisely matches the device array and has hardware for socket mounting.